Making the Skies Safer One Flight at a Time

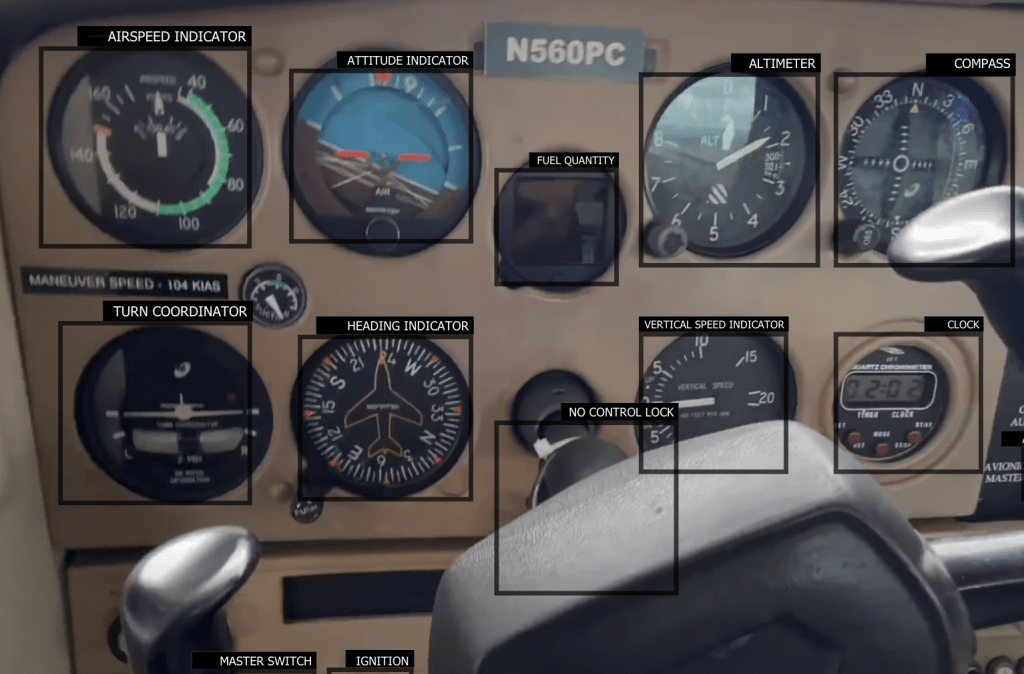

SkyGlass revolutionizes preflight inspection by using live image recognition to identify real-time safety issues and provide a personalized solution.

What does SkyGlass Offer?

Comprehensive Preflight Checks

SkyGlass can analyze both the exterior and interior systems of the aircraft. With its innovative AR technology, pilots and technicians can seamlessly perform walk-arounds while gaining real-time insights in critical aircraft components.

Personalized Inspections

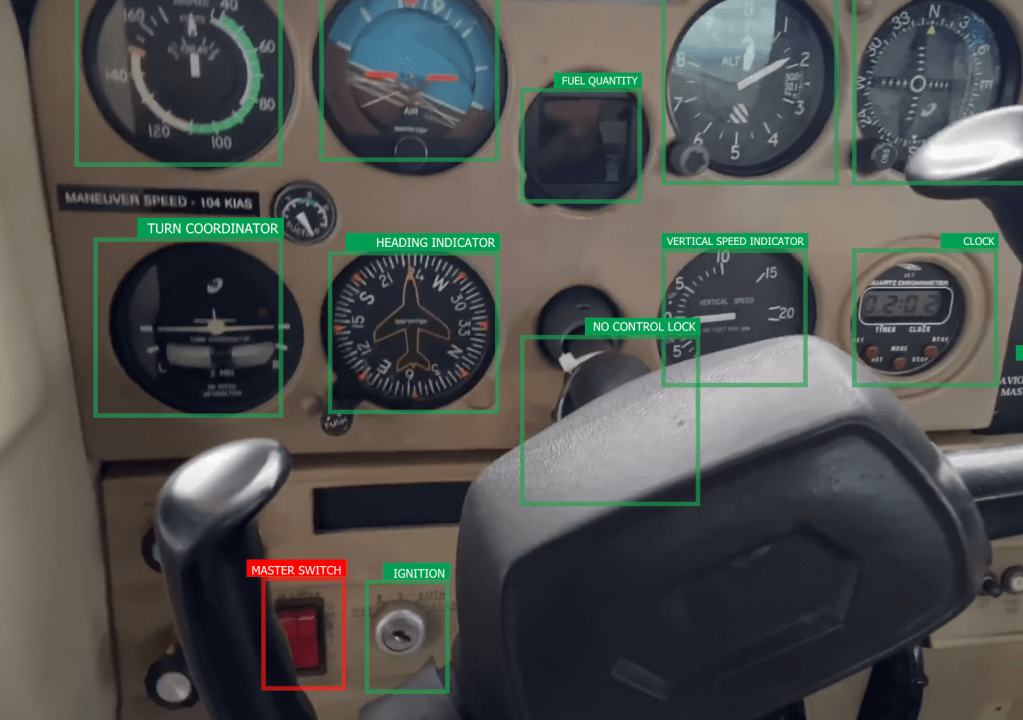

SkyGlass uses AI-powered computer vision to analyze and identify aircraft components during each inspection. This significantly reduces the chances of human error and flags potential issues that might be overlooked during manual inspections.

Easy to Learn Instructions

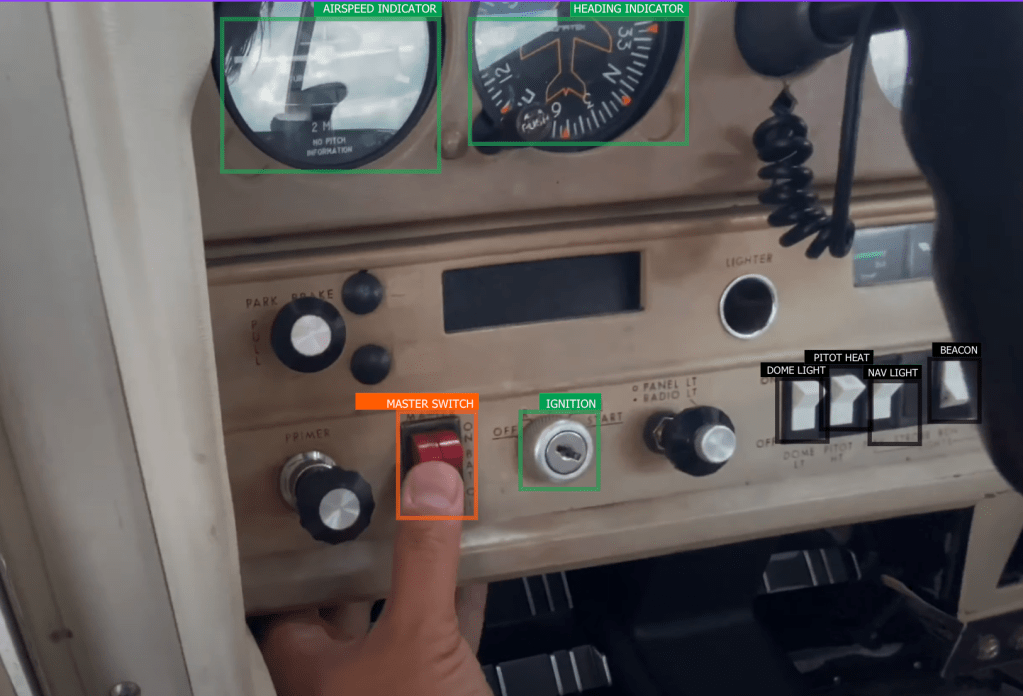

Just learning how to fly? SkyGlass has step-by-step instructions, should any part of the plane need repairs on the go. With a large database of airplane fixes, along with an AR-assisted tutorial, SkyGlass can guide you to fix anything, anywhere.

Aircraft Compatibility

For users unfamiliar with newer aircraft, SkyGlass is highly adaptable to different models and helps student pilots get familiar with a variety of planes. This way, SkyGlass can adapt to the needs of every future pilot, regardless of what they fly.

How Does our YOLO V11 Work?

SkyGlass uses state of the art computer vision models to automate preflight inspections, detecting aircraft component configurations for improved safety.

Step 1: Discovery

Locates all components relevant to the inspection with computer vision

Step 2: Identification

The model sorts preflight components by action needed based on data

Step 3: Solutions

The model refers to a copy of the flight manual

Step 4: Confirmation

Verifies the accuracy of detection algorithms to increase reliability

Technical Overview

SkyGlass reports strong results from our computer vision models, with a high-performing confusion matrix that demonstrates precision in distinguishing between nominal and off-nominal configurations of Cessna 172 components. This accuracy shows our commitment to elevating aviation safety, as our model reliably detects even subtle component discrepancies, advancing our mission for safer skies.